I. Introduction

The automotive industry has long been at the forefront of technological innovation and manufacturing excellence. One of the key materials that have revolutionized this industry is plastic. Plastic components are now integral to the design, performance, and cost-effectiveness of modern vehicles. This article aims to explore the pivotal role of plastic injection molding in meeting the automotive industry's demands for precision, durability, and cost-effective manufacturing processes.

A. Brief Overview of the Automotive Industry’s Reliance on Plastic Components

Plastic components have become ubiquitous in the automotive industry, finding applications in everything from interior trim to exterior body panels. They offer a lightweight alternative to traditional materials, improving fuel efficiency and reducing emissions. Moreover, plastics provide design flexibility, allowing for the creation of complex shapes and integrated features that enhance both aesthetics and functionality.

B. Importance of Efficient and High-Quality Manufacturing Processes in Automotive Production

Efficiency and quality are paramount in automotive production. Manufacturers must ensure that vehicles meet stringent safety and performance standards while also being cost-competitive. High-quality manufacturing processes are essential to achieving these goals, and plastic injection molding stands out as a process that delivers on both fronts.

C. Thesis Statement

Plastic injection molding is a pivotal solution for meeting the automotive industry's demands. It offers a combination of precision, design flexibility, material selection, and cost-effectiveness that is unmatched by other manufacturing methods.

II. Understanding the Automotive Industry’s Needs

To fully appreciate the role of plastic injection molding, it's important to understand the specific needs of the automotive industry.

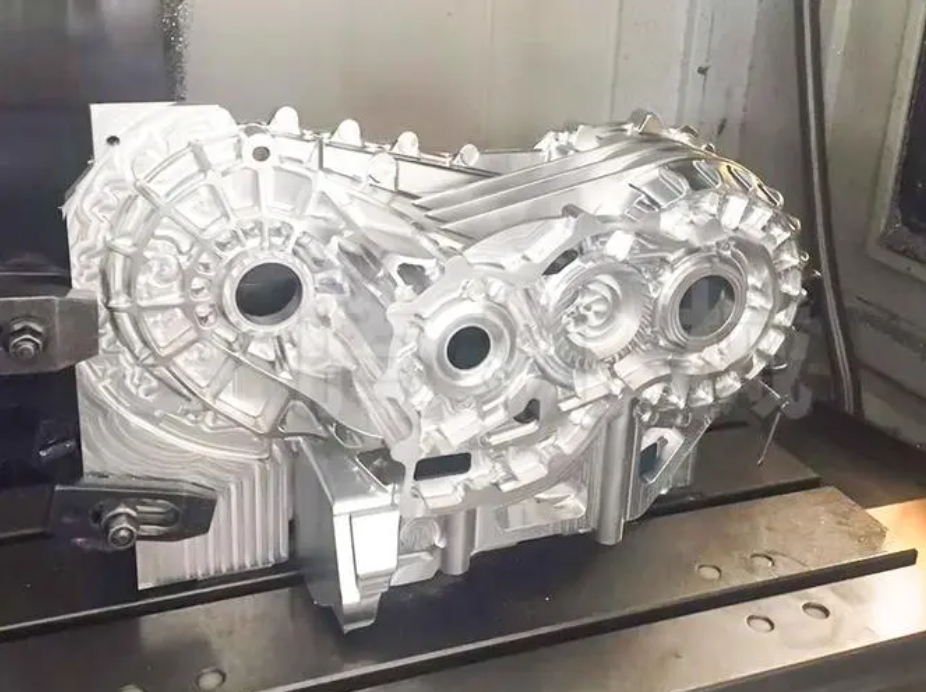

A. Overview of the Diverse Range of Plastic Components Used in Modern Vehicles

Modern vehicles utilize a wide array of plastic components, from small fasteners and connectors to large body panels and structural components. These parts must meet exacting standards for strength, durability, and resistance to environmental factors such as heat, cold, and UV radiation.

B. Emphasizing the Critical Requirements for Precision, Durability, and Cost-Effectiveness

Precision is critical in automotive manufacturing to ensure that parts fit together seamlessly and function as intended. Durability is equally important, as parts must withstand the rigors of daily use and the test of time. Cost-effectiveness is a driving factor in an industry where margins are tight and competition is fierce.

C. Case Studies Highlighting the Significance of Plastic Components in Automotive Design and Functionality

Case studies of successful implementations of plastic components in automotive design can provide valuable insights. For instance, the use of plastic in engine components can lead to weight reduction and improved performance. Similarly, the integration of plastics in vehicle interiors can enhance comfort and aesthetics.

III. Advantages of Plastic Injection Molding

Plastic injection molding offers several advantages that make it an ideal choice for automotive manufacturing.

A. Precision and Consistency

Injection molding ensures tight tolerances and uniformity in automotive parts. This precision is achieved through the use of highly controlled processes and state-of-the-art machinery, which can produce parts with repeatable accuracy.

B. Design Flexibility

One of the standout features of injection molding is its design flexibility. It allows manufacturers to create complex geometries and integrate multiple functionalities into a single component, streamlining production and reducing assembly time.

C. Material Selection

The wide range of resins available for injection molding means that manufacturers can select materials that meet the specific requirements of different automotive applications. This includes materials with varying degrees of strength, flexibility, and resistance to environmental factors.

D. Cost-Effectiveness

The economic benefits of injection molding for large-scale automotive production are significant. The process allows for high-volume production with minimal waste, leading to lower costs per part and a faster return on investment.

IV. Enhancing Automotive Manufacturing Efficiency

In addition to its inherent advantages, injection molding also contributes to enhancing the overall efficiency of automotive manufacturing.

A. Rapid Prototyping

Injection molding facilitates quick iteration and validation of automotive part designs. This rapid prototyping capability allows manufacturers to test and refine designs before committing to large-scale production, reducing development time and costs.

B. Just-in-Time Manufacturing

The on-demand nature of injection molding supports just-in-time (JIT) manufacturing practices. This approach to inventory management ensures that parts are produced as needed, reducing storage costs and minimizing the risk of obsolescence.

C. Tooling Innovations

Advancements in mold design and manufacturing techniques have made injection molding even more efficient for automotive applications. Modern tooling can produce parts with greater complexity and precision, while also reducing the time and cost associated with tooling production.

V. Quality Assurance and Regulatory Compliance

Quality and compliance are non-negotiable in the automotive industry, and injection molding meets these needs head-on.

A. Ensuring Durability and Performance

Rigorous testing and quality control measures are integral to plastic injection molding for automotive components. These processes ensure that parts meet the high standards required for durability and performance in automotive applications.

B. Meeting Industry Standards

Adherence to automotive industry regulations and certifications for safety and reliability is a must. Injection molding processes are designed to meet these standards, ensuring that parts are not only functional but also safe for use in vehicles.

VI. Sustainability and Environmental Impact

In an industry increasingly focused on sustainability, the environmental impact of manufacturing processes is a critical consideration.

A. Eco-Friendly Practices

Plastic injection molding is an eco-friendly practice due to its recyclability and sustainability aspects. Many plastics used in automotive manufacturing can be recycled, reducing waste and the industry's overall environmental footprint.

B. Reduced Material Waste

The efficiency of injection molding processes in minimizing material scrap is another sustainability benefit. By producing parts with high precision and minimal waste, injection molding helps to conserve resources and reduce the industry's impact on the environment.

VII. Case Studies and Success Stories

Real-world examples can provide a compelling argument for the benefits of plastic injection molding in the automotive industry.

A. Showcasing Real-World Examples

Case studies of automotive companies that have successfully implemented plastic injection molding for various components can offer valuable insights. These examples can highlight improvements in product performance, cost savings, and market competitiveness.

B. Analyzing the Impact

A detailed analysis of the impact of injection molding on these companies can reveal the tangible benefits of this manufacturing process. This includes not only cost savings but also improvements in product quality and customer satisfaction.

VIII. Future Trends and Innovations

Looking ahead, the future of automotive manufacturing is set to be shaped by further integration of advanced technologies and materials.

A. Industry 4.0 Integration

The role of automation, digitalization, and smart manufacturing in the future of automotive component production is significant. Injection molding is well-positioned to benefit from these trends, with the potential for increased efficiency and precision through the use of advanced technologies.

B. Advanced Materials and Technologies

Emerging trends in resin development and additive manufacturing for automotive applications are set to further enhance the capabilities of injection molding. These innovations could lead to the creation of even more advanced and efficient automotive components.

In conclusion, the advantages of plastic injection molding for automotive components are clear. The process offers a unique combination of precision, design flexibility, material selection, and cost-effectiveness that is essential for meeting the demands of the automotive industry.

The recapitulation of these advantages underscores the value that injection molding brings to the automotive manufacturing process. It is a solution that not only meets current needs but is also adaptable to future challenges and opportunities.

The pivotal role of injection molding in driving efficiency, quality, and innovation in the automotive industry cannot be overstated. It is a process that is fundamental to the industry's ability to produce high-quality vehicles that are safe, reliable, and cost-competitive.

At Foshan Hongshuo Mold Co., Ltd., we understand the importance of precision and accuracy in mold manufacturing. We have the ability to produce 200 sets of precision molds per month and have the ability to inject 200,000 to 500,000 plastic parts. These numbers underscore our commitment to timely and efficient production, ensuring our customers can rely on us to meet their manufacturing needs.

Our molds have been exported to over 20 countries around the world, a testament to our dedication and superior craftsmanship. Our strong global presence includes markets such as Russia, Canada, Egypt, Israel, Spain and Poland. This broad reach reflects our commitment to providing exceptional quality and reliable service to our international customers.

Feel free to contact us anytime ! We're here to help and would love to hear from you.

Adress: Fourth Floor, No. 32, Xinghua East Road, Ronggui Bianjiao Neigborhood Committee, Shunde District, Foshan City

Phone:+8618024929981

Whatsapp:8618029248846

mail: molly@m-stephome.com

Sales Executive

Post time: May-28-2024