Previous Molds making and Free products design

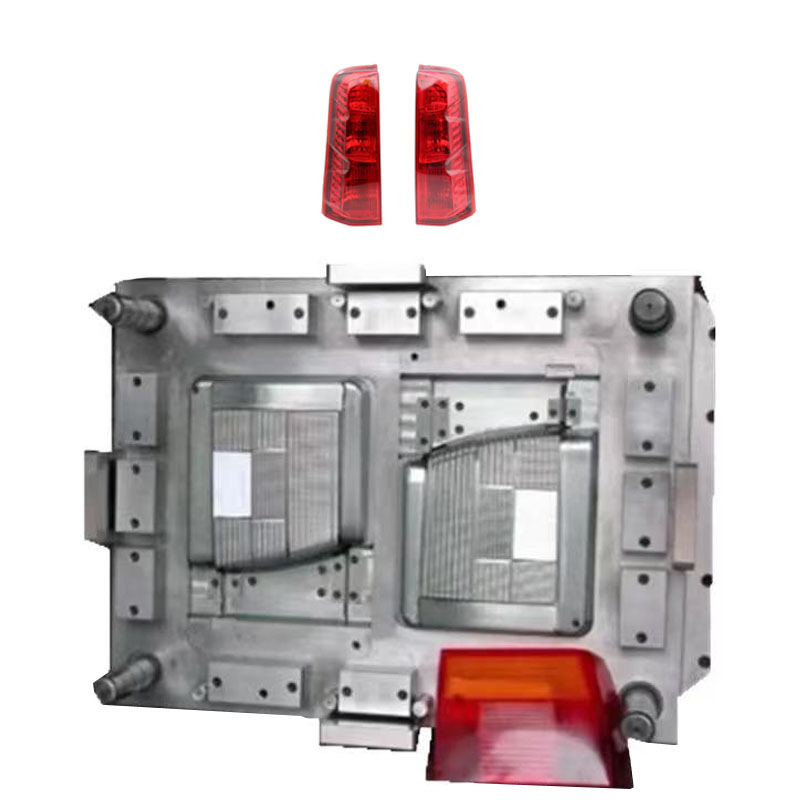

Plastic Injection Mold Components

Meeting Custom Plastic Component Needs With Exceptional Service

With years of experience and a well-equipped production base equipped with advanced machinery, our company is committed to providing excellence in service for Plastic Injection Mold Components. We understand the importance of custom plastic parts to meet customer specific requirements. With our in-house design and manufacturing capabilities, we are able to craft attractive designs that meet your custom plastic part needs.

In our company, we prioritize customer satisfaction by providing a comprehensive service for Plastic Injection Mold Components. Through proper evaluation of your prototypes and samples, we carefully develop unique product designs that meet your needs. We know that every project is unique and requires a tailored approach. That's why our team of experienced professionals work closely with you to ensure your custom plastic parts are designed and manufactured to the highest standards.

One of the main advantages of choosing our plastic injection mold component services is our ability to provide fully customized solutions. We understand that your plastic parts need to fit seamlessly into your product or manufacturing process. Therefore, we can flexibly customize the size, shape and color of plastic parts. Whether you need a specific size to fit a specific space, or a unique shape to enhance the beauty of your product, we have the expertise to meet your requirements.

Our commitment to quality and precision is reflected in every step of the manufacturing process. We employ advanced machinery and technology to ensure your custom plastic parts are produced with the highest precision. From the selection of high-quality materials to the final inspection, we adhere to strict quality control measures to guarantee the durability and functionality of the products. You can rely on us to supply plastic parts that not only meet your expectations, but also comply with industry standards and regulations.

In addition to superior design and manufacturing capabilities, our company prides itself on providing exceptional customer service. We know that clear communication and timely responses are critical to a successful collaboration. Our team of dedicated professionals stands ready to address any queries or concerns you may have throughout the process. We value your trust in our service and strive to exceed your expectations by delivering exceptional results.

When it comes to meeting your custom plastic parts needs, our company is the ideal choice. With years of experience, state-of-the-art machinery and a commitment to quality, we are confident in our ability to deliver exceptional results. Whether you need plastic parts for the automotive, electronics or consumer goods industries, we have the expertise and resources to meet your specific needs. Contact us today to discuss your needs and let us embark on the journey of turning your ideas into reality.

Product Detail

| Place of Origin | China |

| Brand Name | HSLD/ Customized |

| Shaping Mode | Fans Plastic Injection Mould |

| Equipment | CNC, EDM Cutting off Machine, Plastic Machinery, etc |

| Product Material | Steel: AP20/718/738/NAK80/S136 Plastic: ABS/PP/PS/PE/PVC/PA6/PA66/POM |

| Mold Life | 300000~500000 Shots |

| Runner | Hot Runner or Cold Runner |

| Gate type | Edge/Pin point/Sub/Side Gate |

| Surface treatment | Matte, Polished, Mirror polished, texture, painting, etc. |

| Mold Cavity | Single or Multiply Cavity |

| Tolerance | 0.01mm -0.02mm |

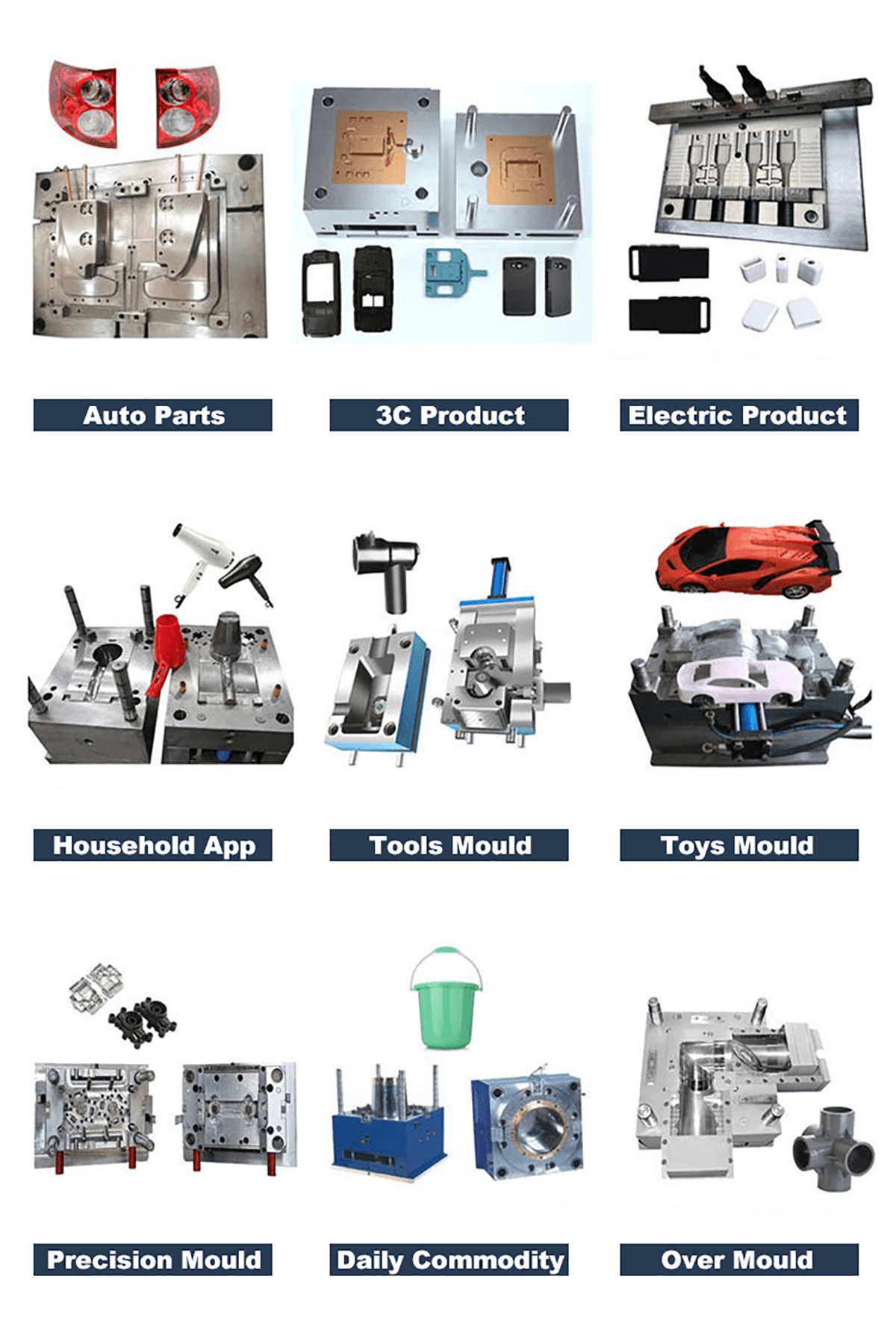

| Injection Machine | 80T-1200T |

| Tolerance | ± 0.01mm |

| Free sample | available |

| Advantage | one stop solution/free design |

| Application field | Electronic products, beauty products, medical products, Home used products, Auto products, etc |

Factory Details

More Molds

Shipment

Special packaging service for you: Wooden case with film

1. To better ensure the safety of your goods, professional.

2. Good to environment, convenient and efficient packaging services will be provided.

FAQ

HSLD: Yes, normally the spare parts for die casting mould we have mould insert, mould frame, window core, moving core, head of nozzle. You can check and inform what spare parts you need.

HSLD: Our mold insert is made of DAC.

HSLD: Our moving core is made of FDAC.

HSLD: Yes.

HSLD: Different equipment has different accuracy, generally between 0.01-0.02mm