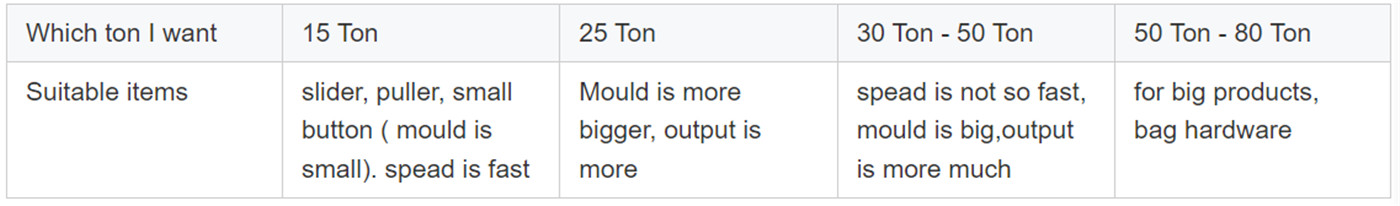

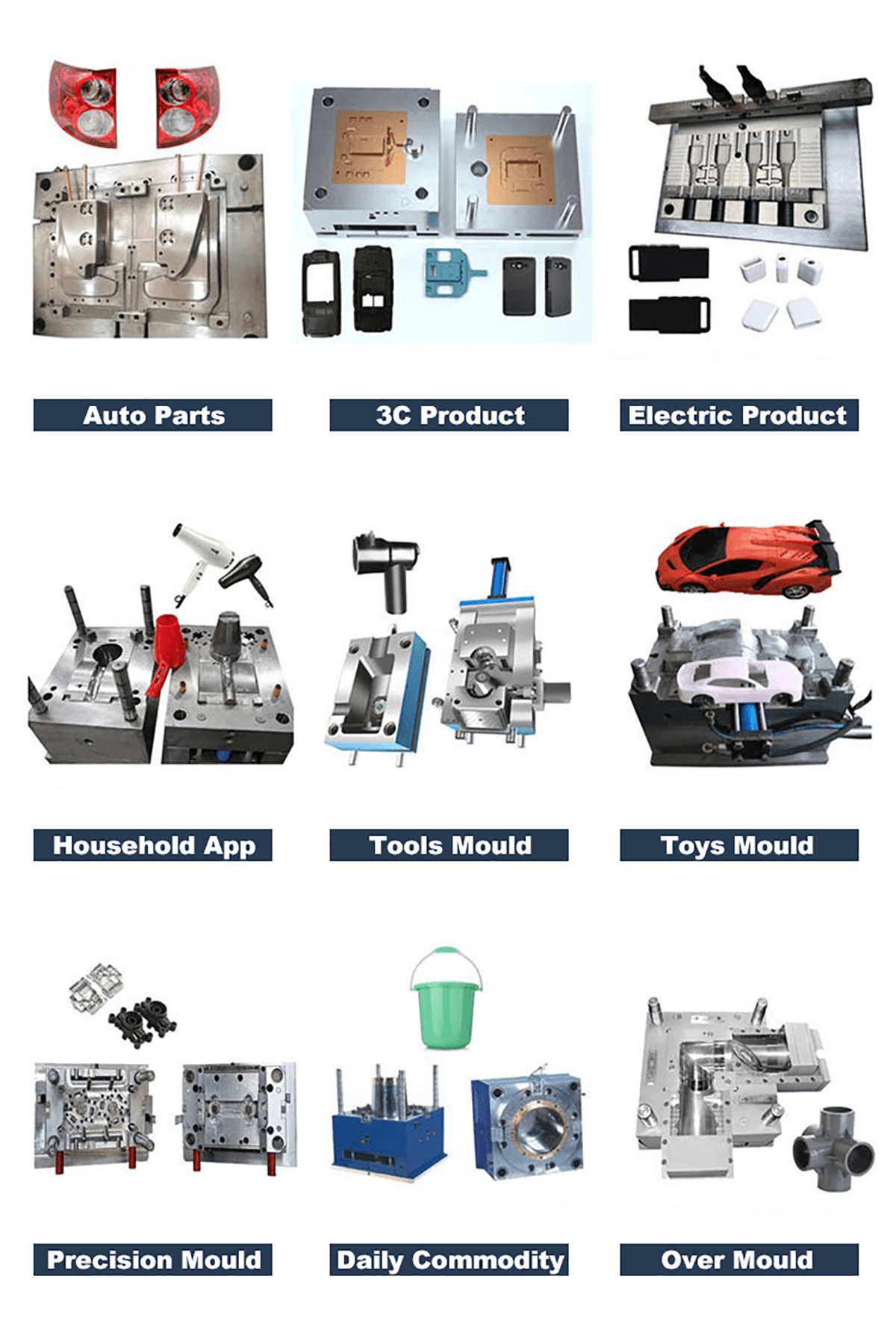

Previous Molds making and Free products design

Plastic Injection Molding for Home Appliances

Plastic injection molding has revolutionized manufacturing, allowing companies to easily create high-quality, high-volume-production plastic parts. However, the process of developing injection molds can be time-consuming and costly. To address these challenges, 3D printing technology has been a game changer, offering more efficient and cost-effective solutions. In this article, we will explore the benefits and applications of 3D printing for plastic injection molds and discuss the services offered by our company.

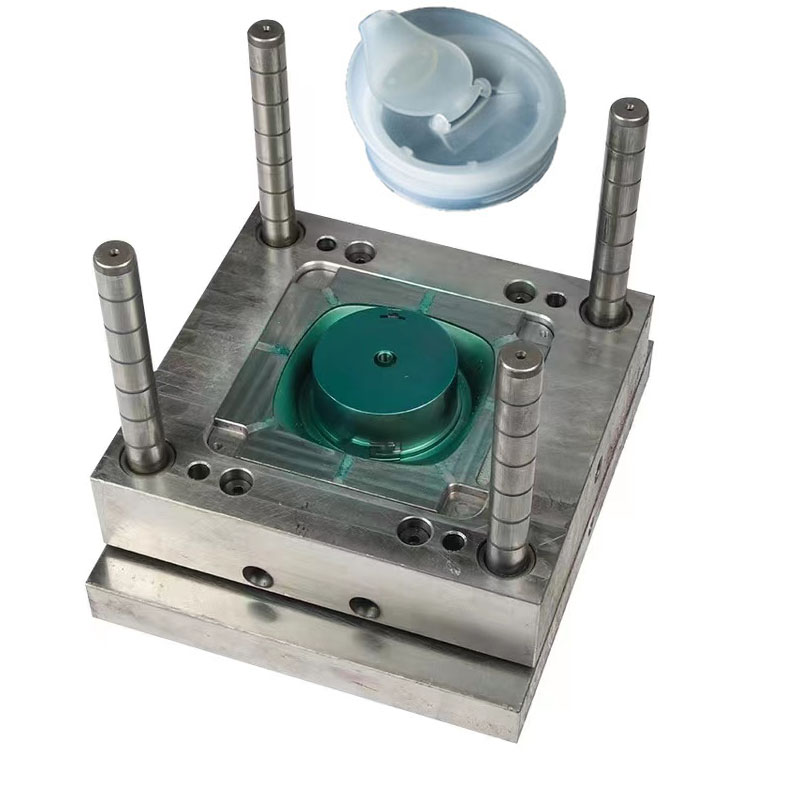

Our company is an OEM/ODM manufacturer specializing in the design and manufacture of injection molds. We understand the importance of enhancing production processes and ensuring greater precision. To achieve this, we employ state-of-the-art 3D printers to create high-definition prototypes. These cutting-edge machines have brought us enormous benefits, revolutionizing the way we design and manufacture injection molds.

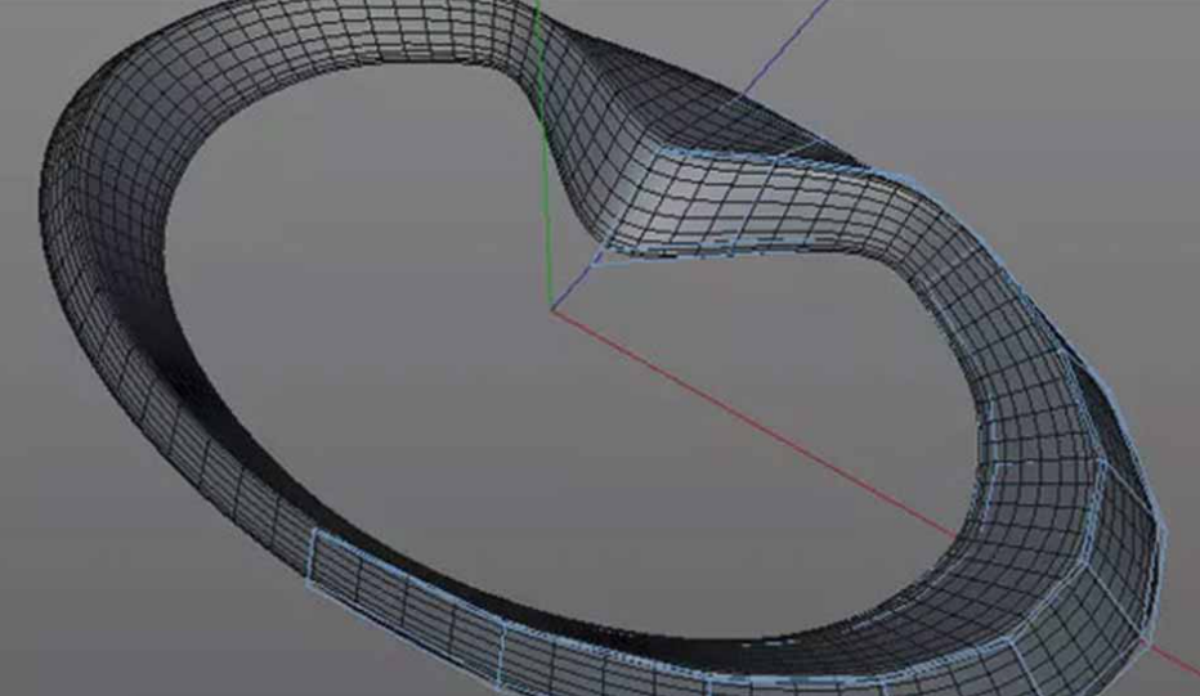

The first advantage of utilizing 3D printing technology is the ability to produce complex sample designs at an affordable price. Traditional methods of mold production often involve complex machining processes that are expensive and time-consuming. 3D printing allows us to create complex and highly detailed designs directly from digital models, eliminating the need for extensive physical labor. This allows us to provide cost-effective solutions without compromising tooling complexity and quality.

Another significant advantage of 3D printing plastic injection molds is the ease with which designs can be corrected on the fly. Traditional mold production methods often require time-consuming modifications and adjustments, resulting in delays in production schedules. However, 3D printing allows us to see and identify design flaws or improvements in real time. By quickly iterating through multiple design revisions, we can significantly reduce the time it takes to complete a mold design. This not only speeds up the production process, but also ensures that the final mold meets the required specifications.

In addition, 3D printing technology allows us to try different materials and test the functionality of the molds before going into mass production. This flexibility allows us to make informed decisions about material selection, ensuring the final mold performs at its best during the injection molding process. Through thorough material testing with 3D printed prototypes, we can eliminate potential issues and reduce overall production costs.

In addition, 3D printing increases the scalability and versatility of mold production. Traditional methods often require creating custom tooling for each unique design, resulting in additional costs and lead times. With 3D printing, we can make molds of various sizes and complexities using the same equipment. This agility allows us to meet a wide range of customer needs and gives us a competitive advantage in the marketplace.

Although 3D printing technology brings many benefits to injection molds, it needs to be emphasized that it cannot replace traditional mold production methods. Traditional machining processes still play a vital role in large-scale industrial production. However, by incorporating 3D printing into our workflow, we can streamline the mold development process, reduce costs and improve overall efficiency.

In summary, our company provides excellence in injection mold production utilizing state-of-the-art 3D printing technology. With our expertise in mold design and manufacturing, combined with the advantages offered by 3D printing, we can provide high quality molds at an affordable price. The use of 3D printing technology allows us to create complex sample designs, revise designs instantly, try different materials, and increase scalability and versatility. By combining the advantages of traditional and modern manufacturing methods, we ensure our customers receive the best solution for their plastic injection molding needs.

Product Detail

| Place of Origin | China |

| Brand Name | HSLD/ Customized |

| Shaping Mode | Fans Plastic Injection Mould |

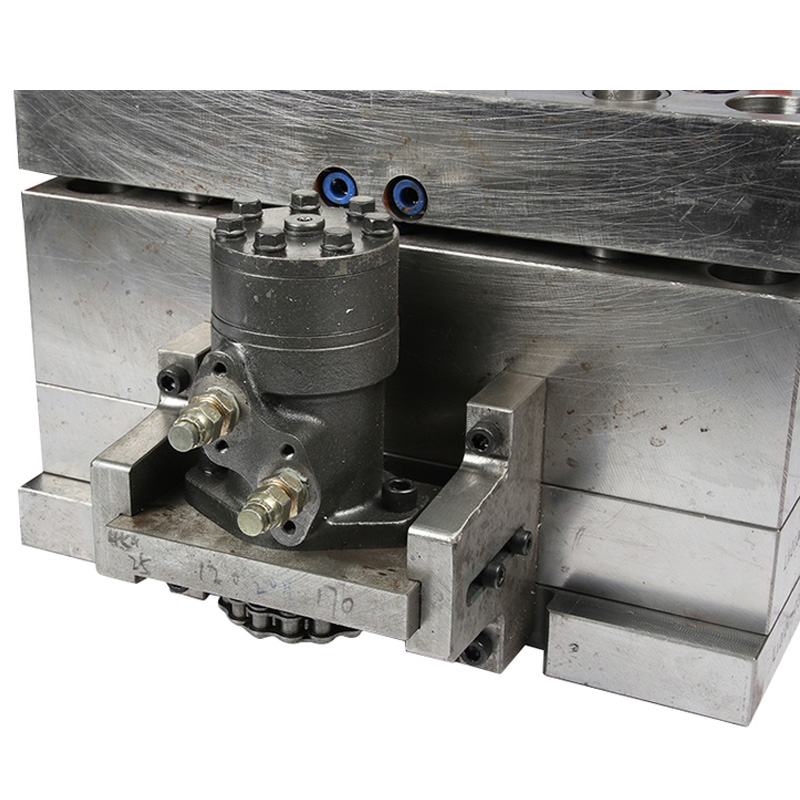

| Equipment | CNC, EDM Cutting off Machine, Plastic Machinery, etc |

| Product Material | Steel: AP20/718/738/NAK80/S136 Plastic: ABS/PP/PS/PE/PVC/PA6/PA66/POM |

| Mold Life | 300000~500000 Shots |

| Runner | Hot Runner or Cold Runner |

| Gate type | Edge/Pin point/Sub/Side Gate |

| Surface treatment | Matte, Polished, Mirror polished, texture, painting, etc. |

| Mold Cavity | Single or Multiply Cavity |

| Tolerance | 0.01mm -0.02mm |

| Injection Machine | 80T-1200T |

| Tolerance | ± 0.01mm |

| Free sample | available |

| Advantage | one stop solution/free design |

| Application field | Electronic products, beauty products, medical products, Home used products, Auto products, etc |

Factory Details

More Molds

Shipment

Special packaging service for you: Wooden case with film

1. To better ensure the safety of your goods, professional.

2. Good to environment, convenient and efficient packaging services will be provided.

FAQ

HSLD: Yes, normally the spare parts for die casting mould we have mould insert, mould frame, window core, moving core, head of nozzle. You can check and inform what spare parts you need.

HSLD: Our mold insert is made of DAC.

HSLD: Our moving core is made of FDAC.

HSLD: Yes.

HSLD: Different equipment has different accuracy, generally between 0.01-0.02mm