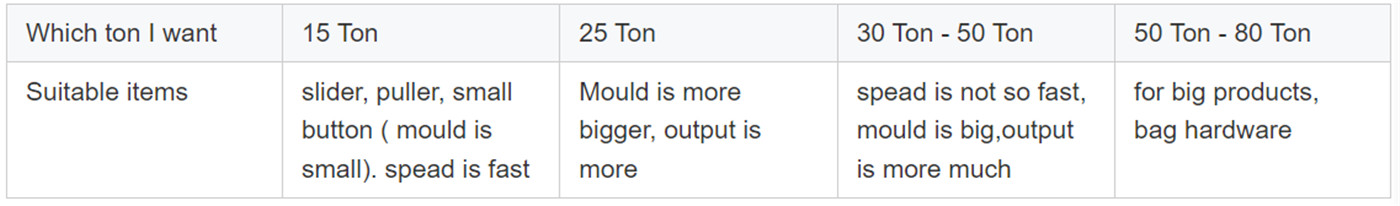

Previous Molds making and Free products design

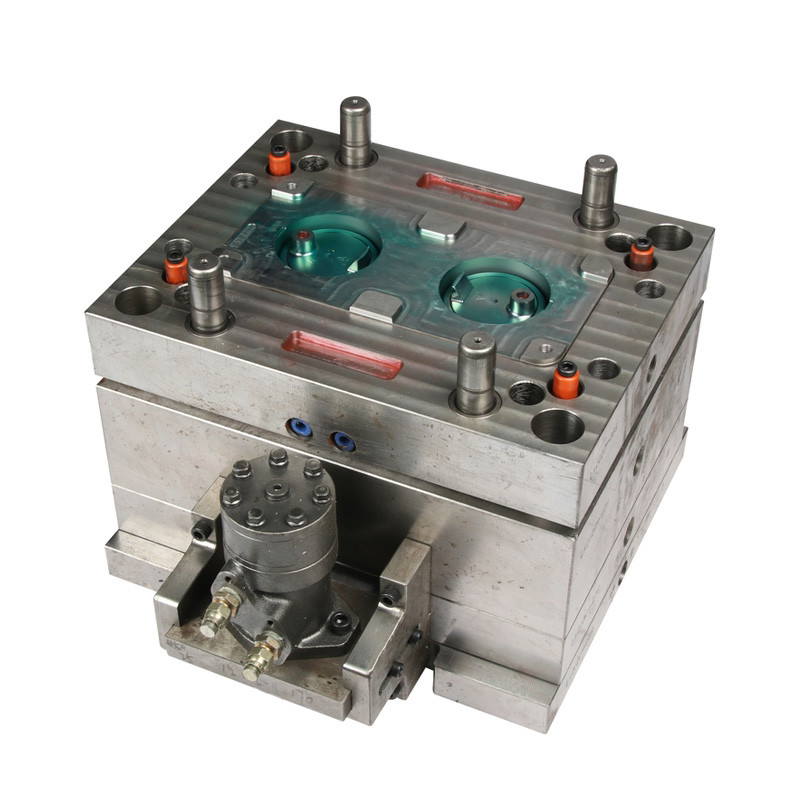

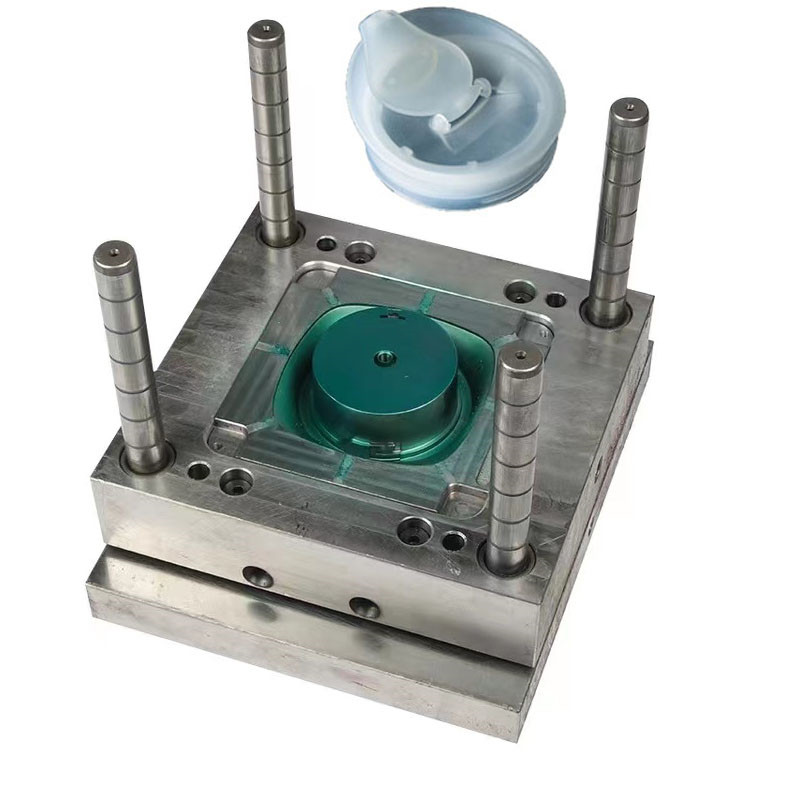

Product Detail

| Place of Origin | China |

| Brand Name | HSLD/ Customized |

| Shaping Mode | Small Home Appliance Plastic Injection Mould |

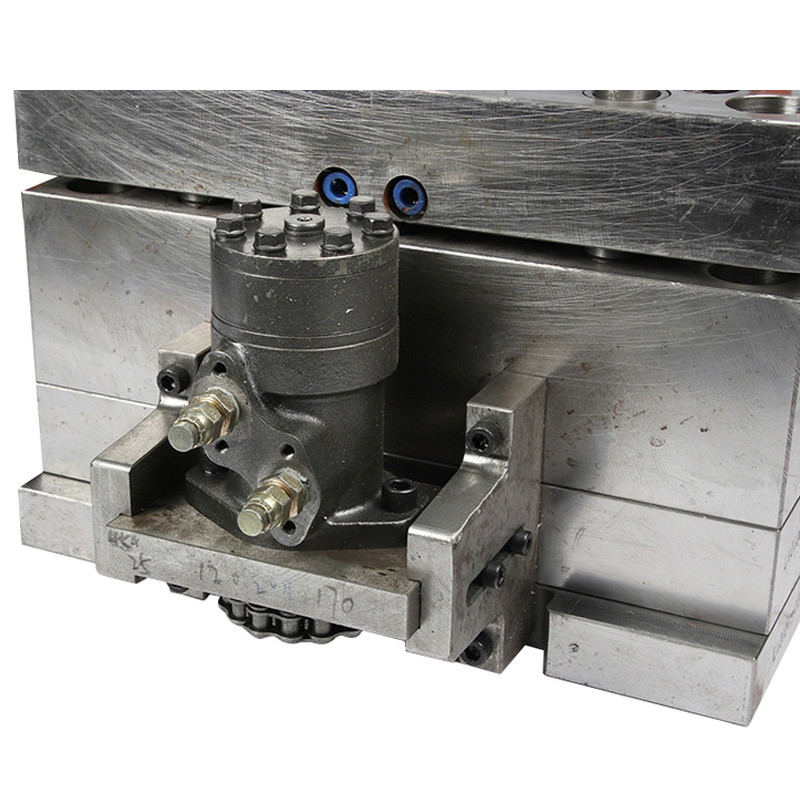

| Equipment | CNC, EDM Cutting off Machine, Plastic Machinery, etc |

| Product Material | Steel: AP20/718/738/NAK80/S136 Plastic: ABS/PP/PS/PE/PVC/PA6/PA66/POM |

| Mold Life | 300000~500000 Shots |

| Runner | Hot Runner or Cold Runner |

| Gate type | Edge/Pin point/Sub/Side Gate |

| Surface treatment | Matte, Polished, Mirror polished, texture, painting, etc. |

| Mold Cavity | Single or Multiply Cavity |

| Tolerance | 0.01mm -0.02mm |

| Injection Machine | 80T-1200T |

| Tolerance | ± 0.01mm |

| Free sample | available |

| Advantage | one stop solution/free design |

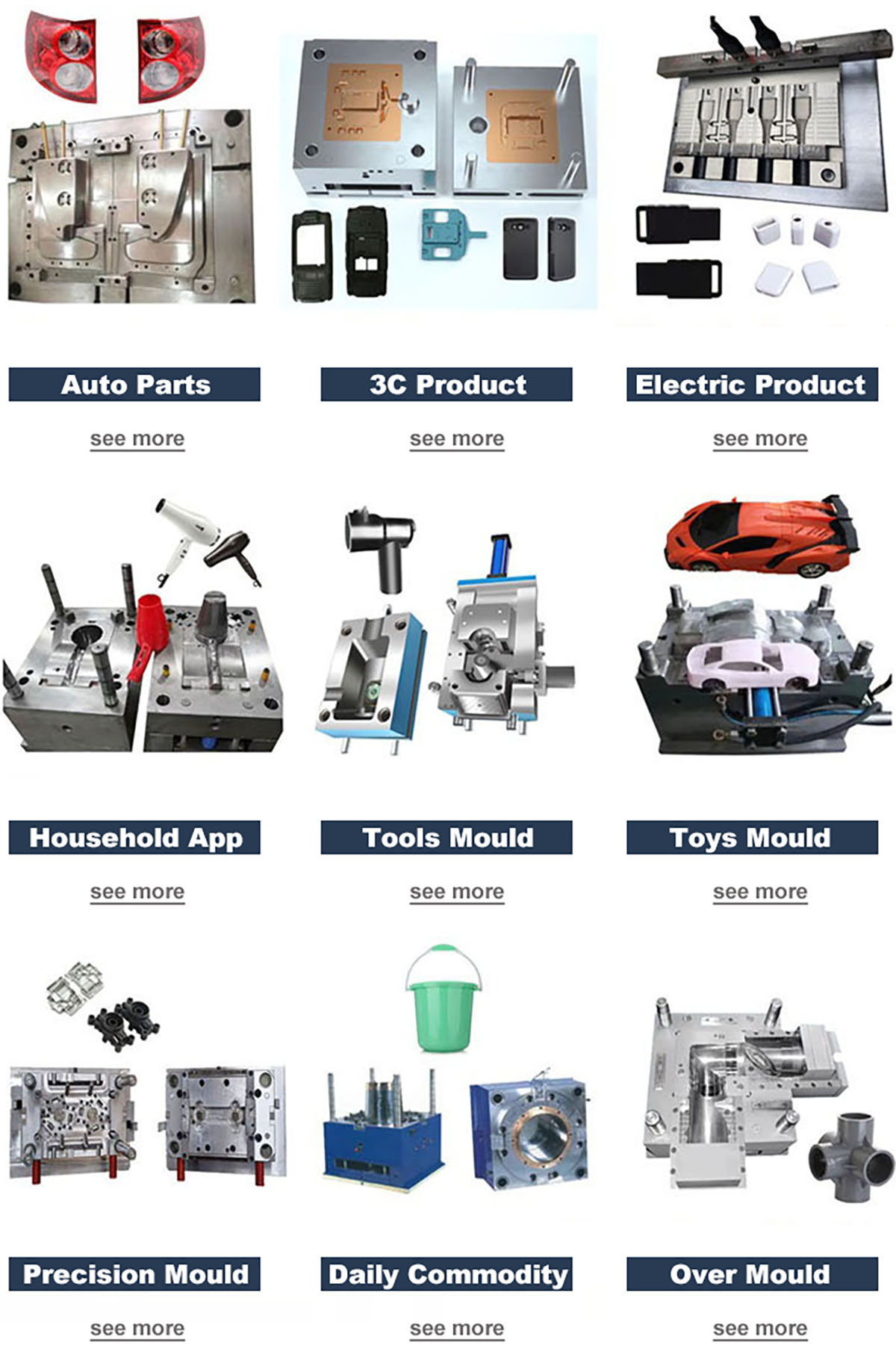

| Application field | Electronic products, beauty products, medical products, Home used products, Auto products, etc |

Video

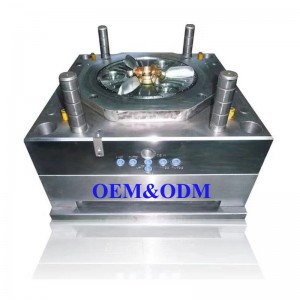

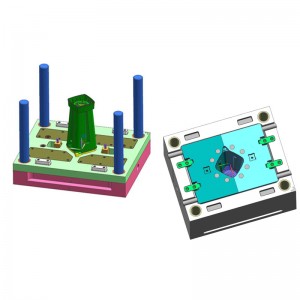

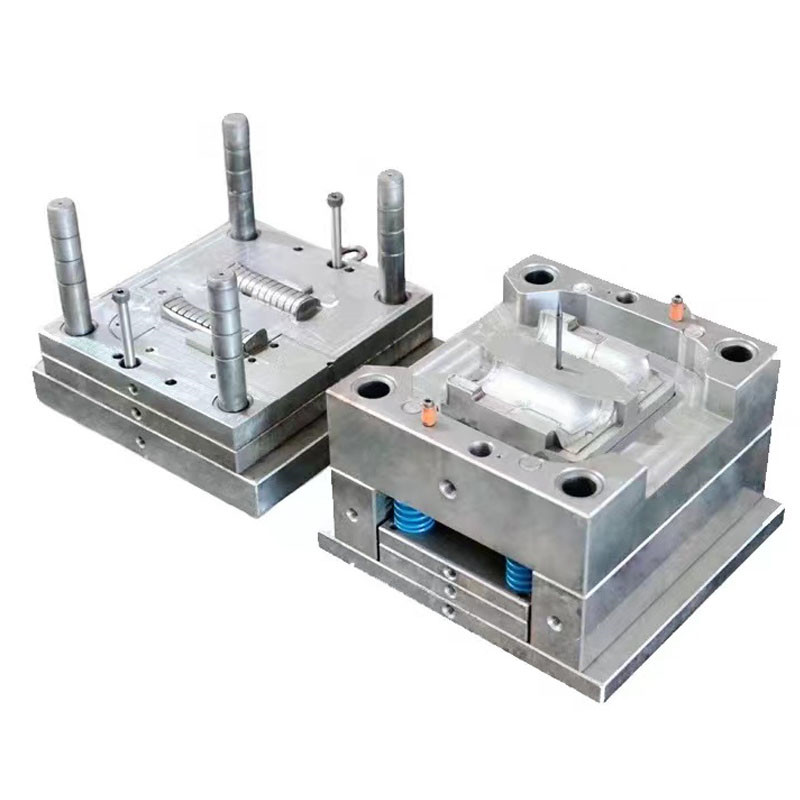

More Molds

Assembly

Products We Made

Shipment and Fair

Special packaging service for you: Wooden case with film

1. To better ensure the safety of your goods, professional.

2. Good to environment, convenient and efficient packaging services will be provided.

Quality is of the utmost importance to us and it shows in every mold we make. We adhere to strict quality control measures throughout the manufacturing process to ensure that the final product meets the exact specifications and requirements of our customers. With our state-of-the-art testing equipment and quality assurance procedures, we guarantee that every mold we produce is of superior quality and built to last.

The combination of our extensive experience, precision and excellent quality makes our products highly sought after in the market. We take great pride in the fact that our molds have become synonymous with reliability and excellence. Our dedication to providing the best products has earned us a loyal customer base and long-term relationships with our clients.

FAQ

HSLD: Yes, normally the spare parts for die casting mould we have mould insert, mould frame, window core, moving core, head of nozzle. You can check and inform what spare parts you need.

HSLD: Our mold insert is made of DAC.

HSLD: Our moving core is made of FDAC.

HSLD: Yes.

HSLD: Different equipment has different accuracy, generally between 0.01-0.02mm

HSLD: It is ok. Surface treatment: spray paint, silk screen, electroplating, etc.