Previous Molds making and Free products design

Top-notch Mold Design for Plastic Components: Customized Solutions

In our company, we specialize in providing first-class service for plastic injection mold components. With the expertise of our engineers, efficient mold designs can be created seamlessly. We understand the importance of creating the perfect mold that embodies your custom plastic part, and we strive to exceed your expectations.

When designing molds for plastic parts, precision and compliance to specifications are critical. Our team of experts works to ensure your mold design meets these standards. We pride ourselves on our ability to manufacture molds that consistently produce high quality plastic parts.

The process starts with understanding your unique needs. We firmly believe in establishing close communication with our customers to fully understand their needs. With a thorough understanding of the plastic parts you need, we can tailor mold designs specifically to your requirements.

After receiving your sample, our experts will conduct a Design for Manufacturability (DFM) analysis report. The analysis is designed to optimize your mold design to ensure accuracy and meet your specifications. We spare no effort in our efforts to provide molds that not only meet your expectations but also increase the efficiency of your production process.

Our DFM analysis reports identify potential issues such as draft angle, wall thickness, gate location, and other critical factors. By addressing these issues early in the design phase, we eliminate the possibility of costly errors during production. Our engineers have the knowledge and experience to optimize your design and ensure seamless production.

Once the mold design is completed, our skilled technicians start the manufacturing process. We utilize state-of-the-art equipment and adhere to strict quality control measures to guarantee the highest level of craftsmanship. Our production facilities are equipped with cutting-edge technology, enabling us to meet the most complex design requirements.

We understand the importance of timely delivery and prioritize efficiency throughout the process. Our streamlined production workflow and efficient project management enable us to deliver your plastic injection mold components within agreed timelines. We strive to be a reliable partner that consistently meets your deadlines and exceeds your expectations.

Additionally, we are committed to continuous improvement and staying abreast of the latest industry trends and technological advancements. Our engineers regularly improve their skills to provide innovative solutions to meet the changing needs of the market. We are confident that our expertise coupled with our dedication to excellence will ensure your satisfaction.

In conclusion, our company provides excellent service for Plastic Injection Mold Components. With the expertise of our engineers, we can seamlessly create efficient mold designs to embody your custom plastic parts. Our DFM analysis reports optimize mold designs to ensure accuracy and compliance to your specifications. Trust us to deliver high-quality plastic injection mold components that meet your deadlines and exceed your expectations.

Product Detail

| Place of Origin | China |

| Brand Name | HSLD/ Customized |

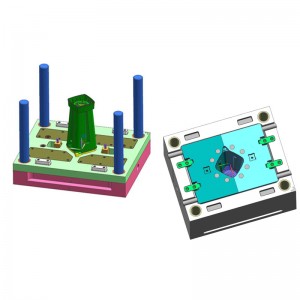

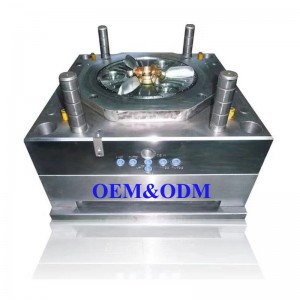

| Shaping Mode | Fans Plastic Injection Mould |

| Equipment | CNC, EDM Cutting off Machine, Plastic Machinery, etc |

| Product Material | Steel: AP20/718/738/NAK80/S136 Plastic: ABS/PP/PS/PE/PVC/PA6/PA66/POM |

| Mold Life | 300000~500000 Shots |

| Runner | Hot Runner or Cold Runner |

| Gate type | Edge/Pin point/Sub/Side Gate |

| Surface treatment | Matte, Polished, Mirror polished, texture, painting, etc. |

| Mold Cavity | Single or Multiply Cavity |

| Tolerance | 0.01mm -0.02mm |

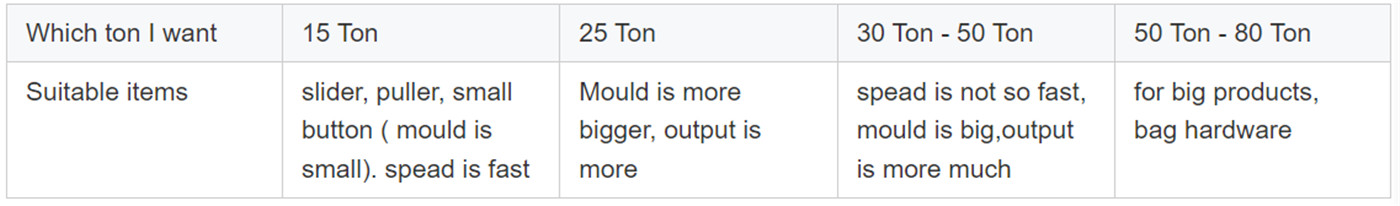

| Injection Machine | 80T-1200T |

| Tolerance | ± 0.01mm |

| Free sample | available |

| Advantage | one stop solution/free design |

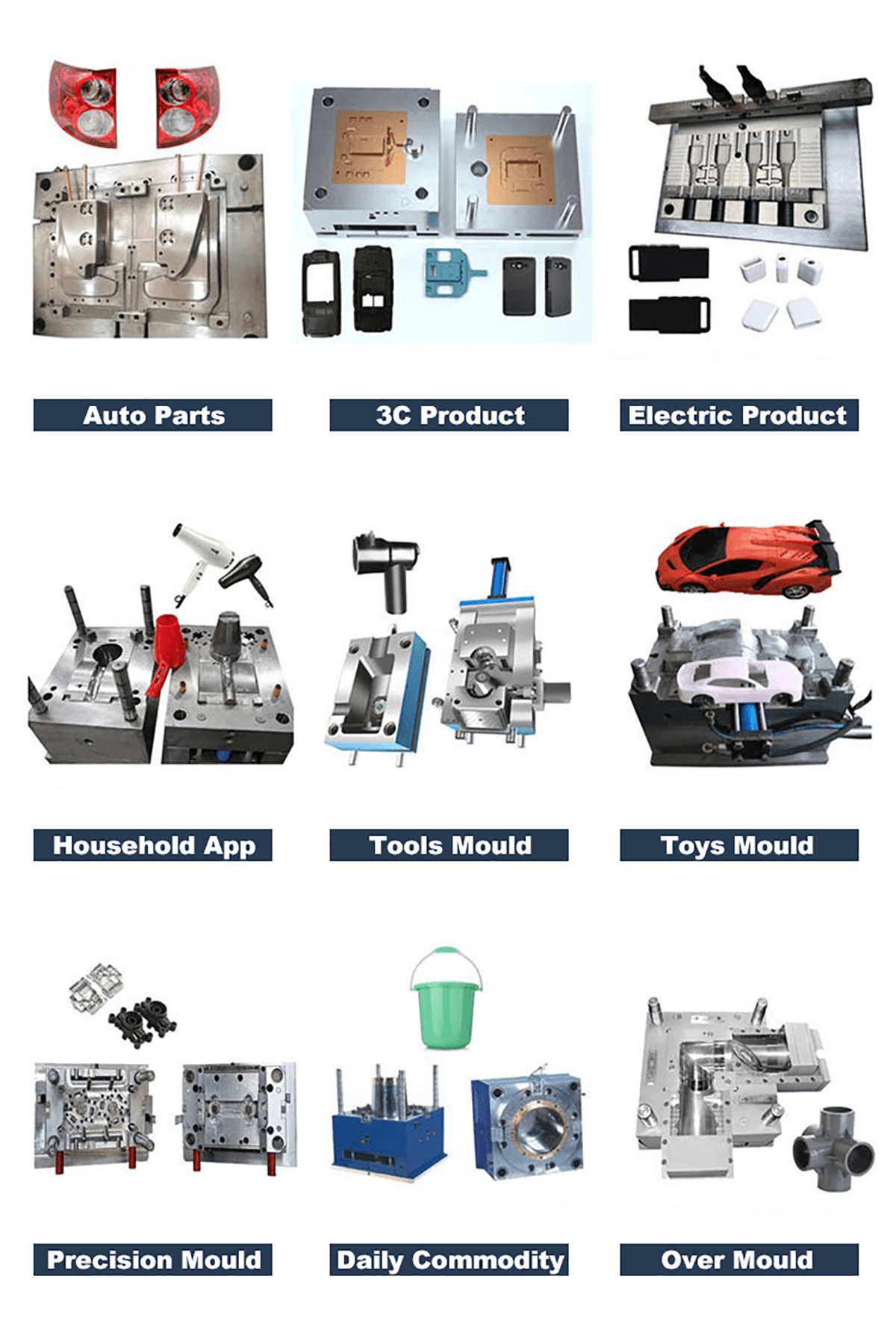

| Application field | Electronic products, beauty products, medical products, Home used products, Auto products, etc |

Factory Details

More Molds

Shipment

Special packaging service for you: Wooden case with film

1. To better ensure the safety of your goods, professional.

2. Good to environment, convenient and efficient packaging services will be provided.

FAQ

HSLD: Yes, normally the spare parts for die casting mould we have mould insert, mould frame, window core, moving core, head of nozzle. You can check and inform what spare parts you need.

HSLD: Our mold insert is made of DAC.

HSLD: Our moving core is made of FDAC.

HSLD: Yes.

HSLD: Different equipment has different accuracy, generally between 0.01-0.02mm