Previous Molds making and Free products design

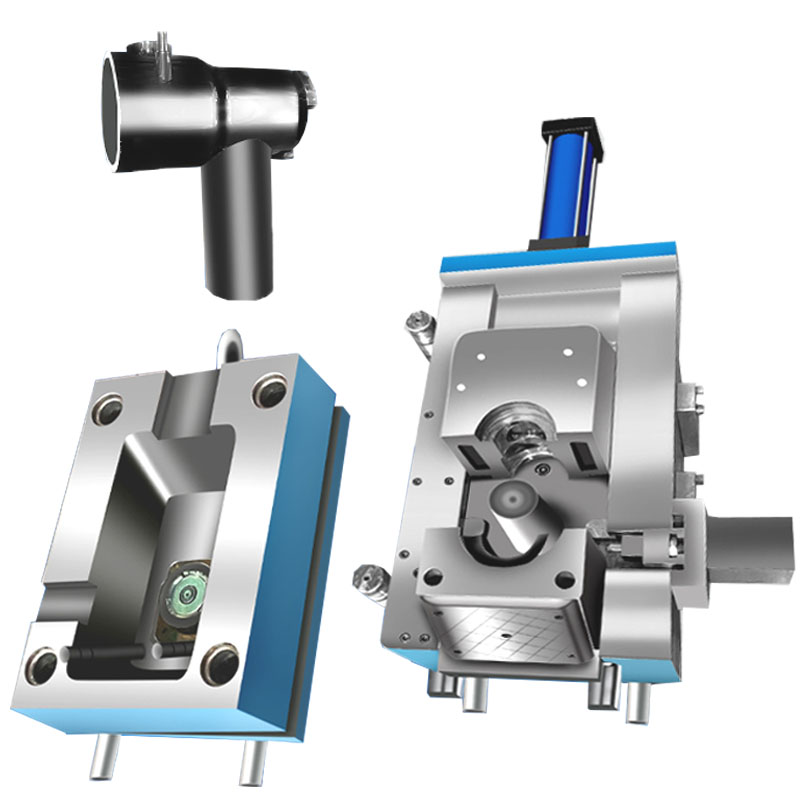

Our Injection Molding Service: Manufacturing Molds Precisely and Efficiently

Hongshuo Mold provides the best injection mold manufacturing services, providing our customers with high-quality molds with precise design and efficient production. With our extensive experience and expertise in injection mold manufacturing, we have the ability to quickly produce thousands of injection mold components, enabling us to fulfill bulk injection mold parts orders in a short period of time.

At Hongshuo Mold, we understand the importance of using high-quality steel in mold production. This ensures that the molds we manufacture are durable, long-lasting and able to withstand the high pressures and temperatures involved in the injection molding process. By using premium materials, we guarantee that our molds will consistently produce high quality plastic parts.

In order to meet the needs of our customers, we have a production capacity of 200 sets of precision molds per month. This enables us to efficiently process large volume orders and deliver molds within agreed timeframes. Additionally, we can inject 200,000 to 500,000 plastic parts per month, ensuring our customers receive the required number of parts to meet their production needs.

Our molds have won recognition and trust from customers all over the world. Our molds have been exported to more than 20 countries, including Russia, Canada, Egypt, Israel, Spain, Poland, Philippines, etc. This international presence is a testament to the quality and reliability of our injection molds.

What sets us apart from other plastic injection mold manufacturers is our dedication to excellence in customer service. We take the time to understand their specific requirements, ensuring their mold designs meet their exact expectations. Our team of skilled engineers and designers work closely with customers to create custom molds that meet their unique needs. We believe effective communication and collaboration are critical in the mold making process, and we strive to build strong relationships with our customers based on trust and transparency.

In addition to excellent mold making services, we also provide comprehensive after-sales service support. We understand that customers may need help or guidance during the mold production process. Our dedicated customer support team is always ready to resolve any concerns or questions our customers may have. We take pride in our ability to provide timely and effective solutions to ensure customer satisfaction.

Hongshuo Mold is committed to continuous improvement and innovation. We regularly invest in the latest technology and equipment to enhance our mold making capabilities. Our team stays abreast of the latest industry trends and advancements, allowing us to incorporate innovative technologies into our moldmaking processes. By maintaining an industry leadership position, we can provide our customers with cutting-edge solutions to meet their ever-changing needs.

Choosing Hongshuo Mold as your injection mold manufacturing partner ensures that you get the highest quality molds tailored to your specific requirements. Our commitment to excellence, efficiency and customer satisfaction sets us apart from our competitors. With our experience, expertise and dedication to service excellence, we are confident that we can exceed your expectations and provide top-notch injection molds for all your plastic part production needs.

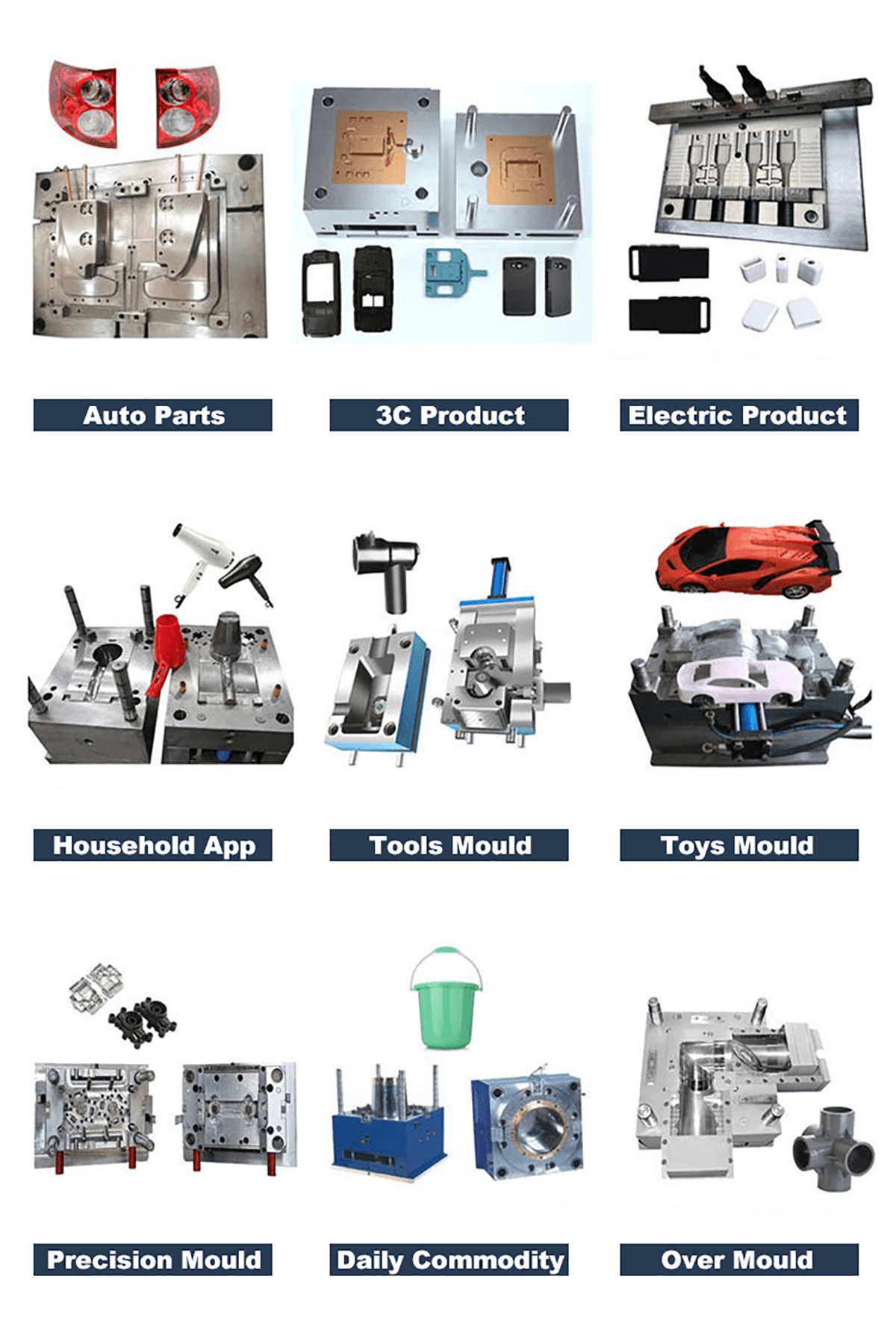

Product Detail

| Place of Origin | China |

| Brand Name | HSLD/ Customized |

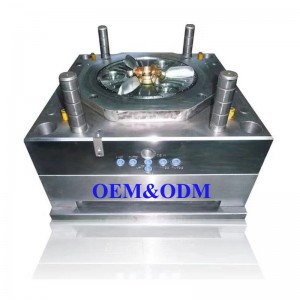

| Shaping Mode | Fans Plastic Injection Mould |

| Equipment | CNC, EDM Cutting off Machine, Plastic Machinery, etc |

| Product Material | Steel: AP20/718/738/NAK80/S136 Plastic: ABS/PP/PS/PE/PVC/PA6/PA66/POM |

| Mold Life | 300000~500000 Shots |

| Runner | Hot Runner or Cold Runner |

| Gate type | Edge/Pin point/Sub/Side Gate |

| Surface treatment | Matte, Polished, Mirror polished, texture, painting, etc. |

| Mold Cavity | Single or Multiply Cavity |

| Tolerance | 0.01mm -0.02mm |

| Injection Machine | 80T-1200T |

| Tolerance | ± 0.01mm |

| Free sample | available |

| Advantage | one stop solution/free design |

| Application field | Electronic products, beauty products, medical products, Home used products, Auto products, etc |

Factory Details

More Molds

Shipment

Special packaging service for you: Wooden case with film

1. To better ensure the safety of your goods, professional.

2. Good to environment, convenient and efficient packaging services will be provided.

FAQ

HSLD: Yes, normally the spare parts for die casting mould we have mould insert, mould frame, window core, moving core, head of nozzle. You can check and inform what spare parts you need.

HSLD: Our mold insert is made of DAC.

HSLD: Our moving core is made of FDAC.

HSLD: Yes.

HSLD: Different equipment has different accuracy, generally between 0.01-0.02mm

-

Popular Plastic Injection Blender Jar Mold: Fac...

-

Plastic Injection Portable Blender Plastic Part...

-

Small Home Appliance Mold Maker Plastic Parts I...

-

Popular Fans Mold Maker Plastic Parts Injection...

-

Plastic Injection for the whole set blender mol...

-

Plastic Injection Moulding For Toy Manufacturing