Previous Molds making and Free products design

Plastic Injection Molding for Home Appliances

Injection molds for home appliances play a vital role in reducing household waste by making parts for various appliances such as washing machines and refrigerators.

Made from durable materials like stainless steel, these molds can be customized to meet the specific needs of each piece of equipment. Hongshuo Mold is a trusted supplier to renowned manufacturers of home appliances supplies. With our comprehensive resource infrastructure, we enable our clients to prioritize two important aspects of the appliance market: zero defects and lower overall costs.

We specialize in manufacturing the following household product parts: household products. Washing machine injection molded parts. Kitchen products. Office printer. computer. Thin-walled food containers.Benefits of Appliance Injection Molding Appliance injection molding involves the use of plastic injection molds to create products designed for appliances.

The process is cost-effective and enables manufacturers to produce products with different functions and designs. Furthermore, it is a sustainable process that reduces waste and energy consumption. Applications of this forming process span automotive, aerospace, medical and home appliances, and excel at producing complex parts with high precision and repeatability. Injection molding for home appliances offers numerous advantages to manufacturers and consumers. It increases design accuracy, reduces production costs and helps make home appliances more efficient, attractive and affordable. Plus, the process often proves to be more environmentally friendly than traditional production methods, making it an excellent choice for those committed to minimizing their environmental impact.

High Strength: Appliance injection molds are designed to produce a wide variety of products, from small kitchen appliances to large appliances. The high strength of these molds ensures the production of quality products that meet the needs of consumers.

Quality Control: Implementing strict quality control measures at every stage of the manufacturing process is essential for appliance injection molds. This ensures that manufactured products meet the highest quality standards. From design to production, meticulous quality control is crucial.

By utilizing appliance injection molds, manufacturers can achieve significant results in waste reduction, energy efficiency, cost-effectiveness and product quality. Partnering with us, together we can pave the way for a sustainable future while achieving exceptional results.

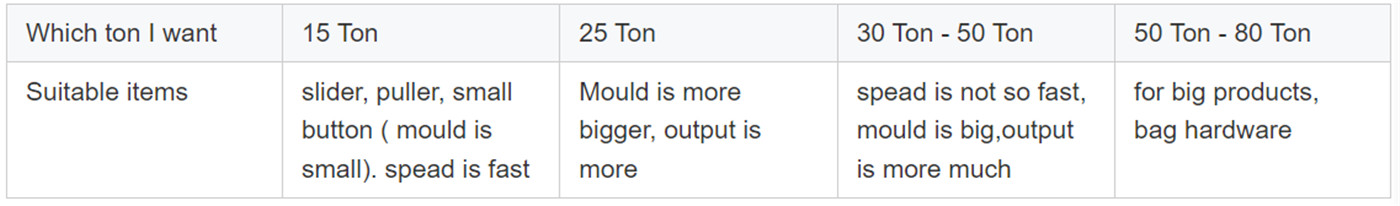

Product Detail

| Place of Origin | China |

| Brand Name | HSLD/ Customized |

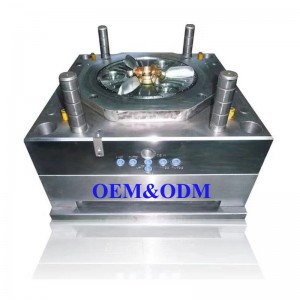

| Shaping Mode | Fans Plastic Injection Mould |

| Equipment | CNC, EDM Cutting off Machine, Plastic Machinery, etc |

| Product Material | Steel: AP20/718/738/NAK80/S136 Plastic: ABS/PP/PS/PE/PVC/PA6/PA66/POM |

| Mold Life | 300000~500000 Shots |

| Runner | Hot Runner or Cold Runner |

| Gate type | Edge/Pin point/Sub/Side Gate |

| Surface treatment | Matte, Polished, Mirror polished, texture, painting, etc. |

| Mold Cavity | Single or Multiply Cavity |

| Tolerance | 0.01mm -0.02mm |

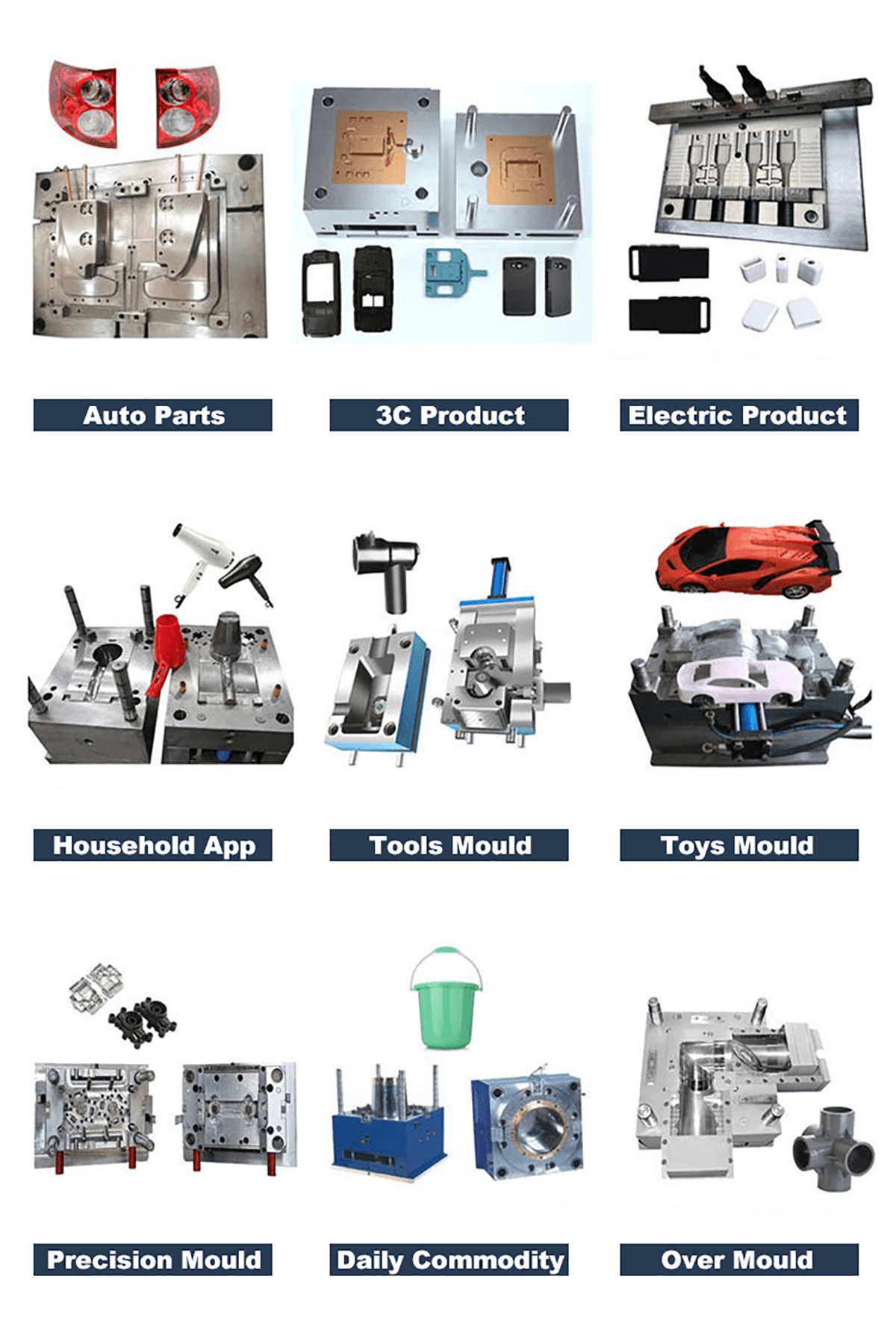

| Injection Machine | 80T-1200T |

| Tolerance | ± 0.01mm |

| Free sample | available |

| Advantage | one stop solution/free design |

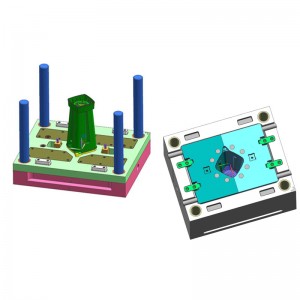

| Application field | Electronic products, beauty products, medical products, Home used products, Auto products, etc |

Factory Details

More Molds

Shipment

Special packaging service for you: Wooden case with film

1. To better ensure the safety of your goods, professional.

2. Good to environment, convenient and efficient packaging services will be provided.

FAQ

HSLD: Yes, normally the spare parts for die casting mould we have mould insert, mould frame, window core, moving core, head of nozzle. You can check and inform what spare parts you need.

HSLD: Our mold insert is made of DAC.

HSLD: Our moving core is made of FDAC.

HSLD: Yes.

HSLD: Different equipment has different accuracy, generally between 0.01-0.02mm